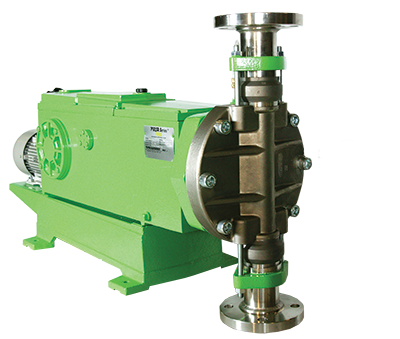

Hydraulically Actuated Diaphragm Pumps

For more than 75 years, positive displacement, reciprocating metering pumps such as Pulsafeeder’s Pulsa Series have led the industry. Now, with the addition of PulsaPro series, we build on the Pulsa legacy and continue the Pulsafeeder tradition of developing hydraulic diaphragm pumps that are the benchmark for safety, reliability and accuracy.

Pulsafeeder Hydraulically Actuated Diaphragm pumps are designed to simplify operation and maintenance – and they ensure dependability with a 5-year drive train warranty.

PulsaPro/Pulsa pumps are widely used in:

Refineries & petrochemical plants

Power plants

Municipal water treatment plants

Upstream oil & gas flow assurance applications

|

Flow

|

Max Pressure

|

Product Line

|

|---|---|---|

|

250 gph

|

3100 psig

|

PulsaPro

|

|

250 gph and up

|

< 500 psig

|

Pulsa Series

|

Pulsa Series

Pulsa Series is available with a variety of diaphragm styles to deliver everything from thin fluids to lime slurries, materials of construction for contact with the most hazardous chemicals and features and options to provide safe, remote and accurate dosing, count on Pulsa Series for the most demanding applications.

The Pulsa Series features:

- Full motion stroke length yields 0-100% flow adjustment

- Linear flow predictability over a 10:1 turndown

- 1% dosing accuracy

- Hydraulically balanced diaphragm for long life and reduced service cost

- Hydraulic management system assures consistent performance

- Internal hydraulic bypass valve for pump protection against system upset

- Epoxy coating resists corrosion from atmospheric contaminants

- 4-Bolt tie-bar valve assembly for service without disturbing system piping

PulsaPro

PulsaPro is the most recent addition to our hydraulically actuated line of products. With automatic degassing features like the HypoValve, API-675 compliance, and certified by WQA to “NSF/ANSI/CAN 61” and “NSF/ANSI 372”, the PulsaPro Series is a perfect fit or Water & Wastewater Treatment, Oil & Gas and Industrial applications.

The PulsaPro series offers a variety of enhancements that:

- Simplify commissioning and start up

- Enhance the pump’s ability to survive upset conditions

- Reduce the pump’s footprint

- Meet API-675 compliance

- Eliminate air binding with the automatic degassing HypoValve

- Certified by WQA to NSF 61 for North America

The latest features in the PulsaPro Series include:

- Push to Purge valve

- High Performance Valve

- Hydraulic Bypass Valve

- 4-Bolt Tie Bar

- Check valves

- Diagnostic Window

- HypoValve